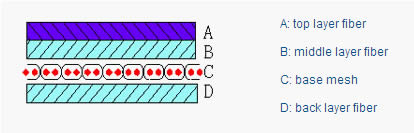

Single-layer BOM

Applicability:

Paper machine type: kinds of paper machine

Machine speed: ≤500m/min

Paper weight: ≥8g/m2kinds of paper

Linear pressure:≤100kN/m

Strength: ≥200N/5cm

Description:

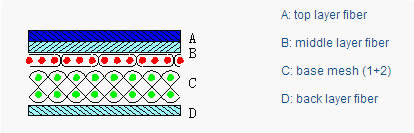

Single-layer BOM is made of single layer base mesh and fiber layer. The base mesh layer is made of nylon yarn or warp and weft weave by doubling monofilament. The stitch structure is designed by different position and different paper of different paper machine. According to the structure of BOM to lay the fiber, having the characteristics of good filterability, small elongation, easy to wash and clean, light mark, affective to eliminate grain mark and other marks, long life and so on. Widely used for kinds of paper machine to product kinds of paper and paper board etc.

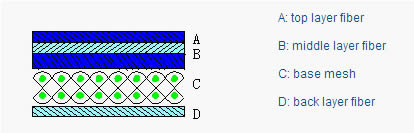

Double-layer BOM

Applicability:

Paper machine type: kinds of paper machine

Machine speed: ≥100m/min

Paper weight: ≥12g/m2kinds of paperLinear pressure:≥100KN/m

Strength: ≥3000N/5cm

Description:

Double-layer BOM is double warp structure BOM. According to paper machine and paper, we can design and change the structure of base mesh. It has the characters of anti-high pressure, good elasticity and filterability, stable size, small elongation, great strength, affective to eliminate grooving, vacuum mark, blind-hole mark and other marks. Suitable to vacuum press, kinds of complex press and other press for producing high grad offset paper, and kinds of high grad paper and paper board etc.

Complex BOM

Applicability:

Paper machine type: kinds of paper machine

Machine speed: ≥200m/min

Paper weight: ≥40g/m2kinds of paper

Linear pressure:≥200kN/m

Strength: ≥4000N/5cm

Description:

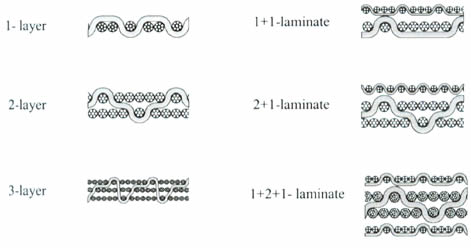

Complex BOM include 1+1, 1+2, 2+1, 1+1+1 BOM. The felts are applicable to 200kN/m even more, have the characters of good flexibility, filterability, stable size and long life, and are affective to eliminate kinds of marks. Suitable width-nip press, shoe press and other press to middle and high speed paper machine for producing high grad paper and paper board etc.

Special papermaking felt

Special papermaking felt includes soft base papermaking felt ,hard base papermaking felt and special base papermaking felt.

Function (after-treatment) papermaking felt

On the base of former felt, the felt is treated by special chemicals, which is better in characters. It includes anti-dirt, anti-fussing, wear-resistant, water-washing and soft treatment papermaking felt. Having the characters of anti-high-press, anti-dirt and anti-fussing and wear-resistant, clean-oneself and easy to wash and clean, long life. Suitable for kinds of paper and paper board and other high grad tissue paper, special paper etc, the felt is used for middle and high-speed paper machine, especially for producing high grad paper and paper board etc, which substitute for imported felts.

Pulp-making felt

The pulp-making felt include BOB pulp-making felt and BOM pulp-making felt, the BOM pulp-making felt include single-layer BOM, double-layer BOM, complex BOM( 1+1, 1+2, 2+1, 1+1+1 ) pulp-making felt, having the characters of good flexibility, filterability, stable size and long life.

Dryer felt

The dryer felt include BOB dryer felt, BOM dryer felt and special dryer felt. The special dryer felt concentrates all excellencies of BOB dryer felt and dryer fabrics, having the characters of good filterability, mark-free, heat-resistant and anti-aging, even structure, wear-resistant, stable size, great strength, easy to operation and long life.

|